Trick Benefits of Using a Membrane Switch in Industrial Applications

Trick Benefits of Using a Membrane Switch in Industrial Applications

Blog Article

Recognizing the Performance of Membrane Layer Switches Over for Individual Interface Gadget

The capability of membrane layer switches over represents a considerable advancement in customer interface style, incorporating performance with visual versatility. As sectors progressively prioritize user experience, comprehending the subtleties of membrane layer button innovation comes to be crucial.

What Are Membrane Layer Switches?

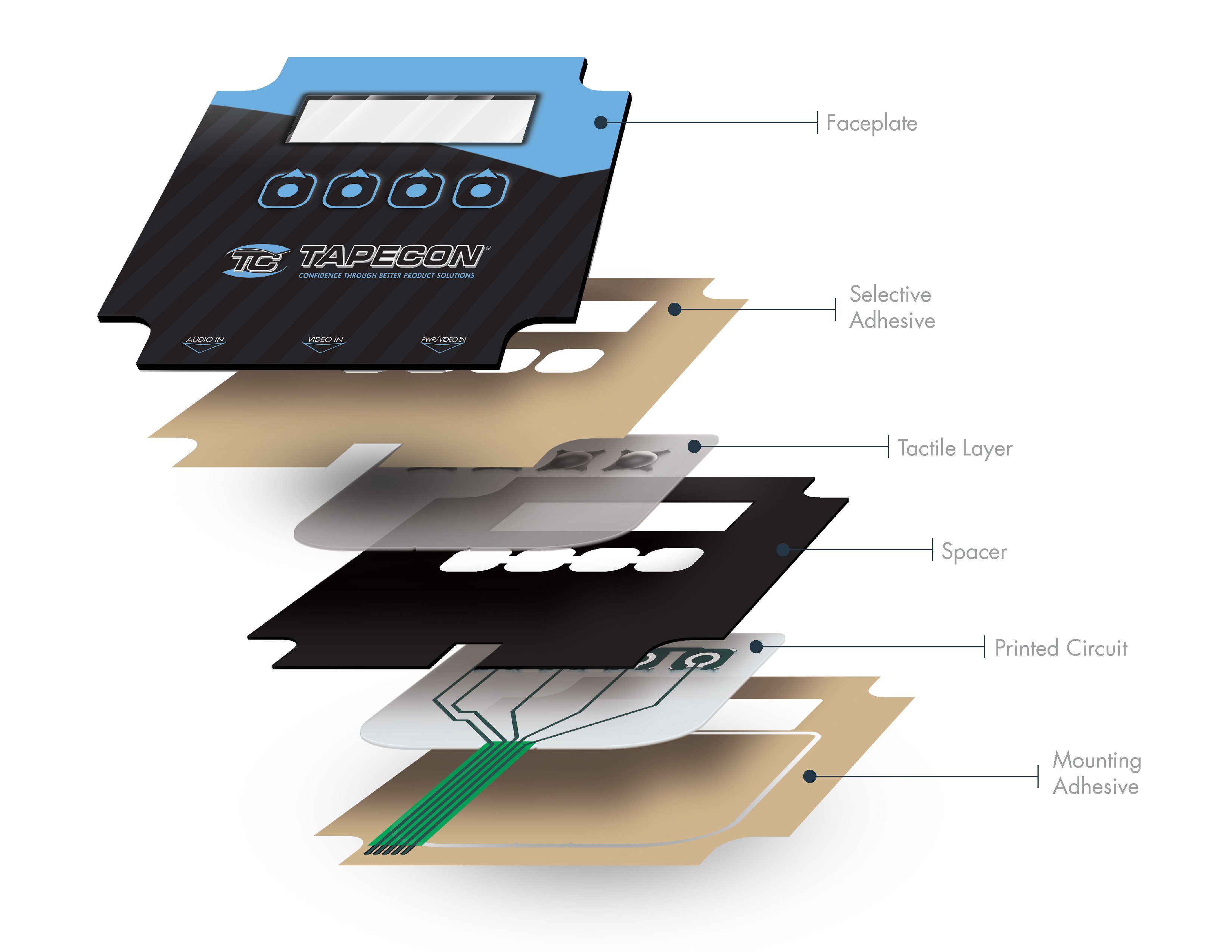

Membrane layer buttons are innovative interface devices that assist in user communication with electronic devices. These flexible parts include numerous layers, consisting of a visuals overlay, spacer, and a printed circuit layer. The layout enables a seamless integration into numerous digital tools, improving both the aesthetic and useful aspects of user interfaces.

Membrane layer switches are typically used in a large range of applications, from household appliances to commercial machinery and clinical devices. Their building and construction normally features a thin account, making them a suitable choice for compact styles. The tactile comments provided by these buttons can be engineered to satisfy specific user choices, making certain efficient communication between the customer and the device.

Resilience is one more significant advantage of membrane layer buttons, as they are immune to dust, dampness, and chemicals, which boosts their life-span popular atmospheres. Additionally, these buttons can be tailored in terms of form, dimension, and visuals layout, enabling branding and user-specific functions. Overall, membrane layer switches over represent a functional option for boosting customer experience in electronic tools, combining capability with visual charm in a reliable fashion.

Just How Membrane Layer Switches Work

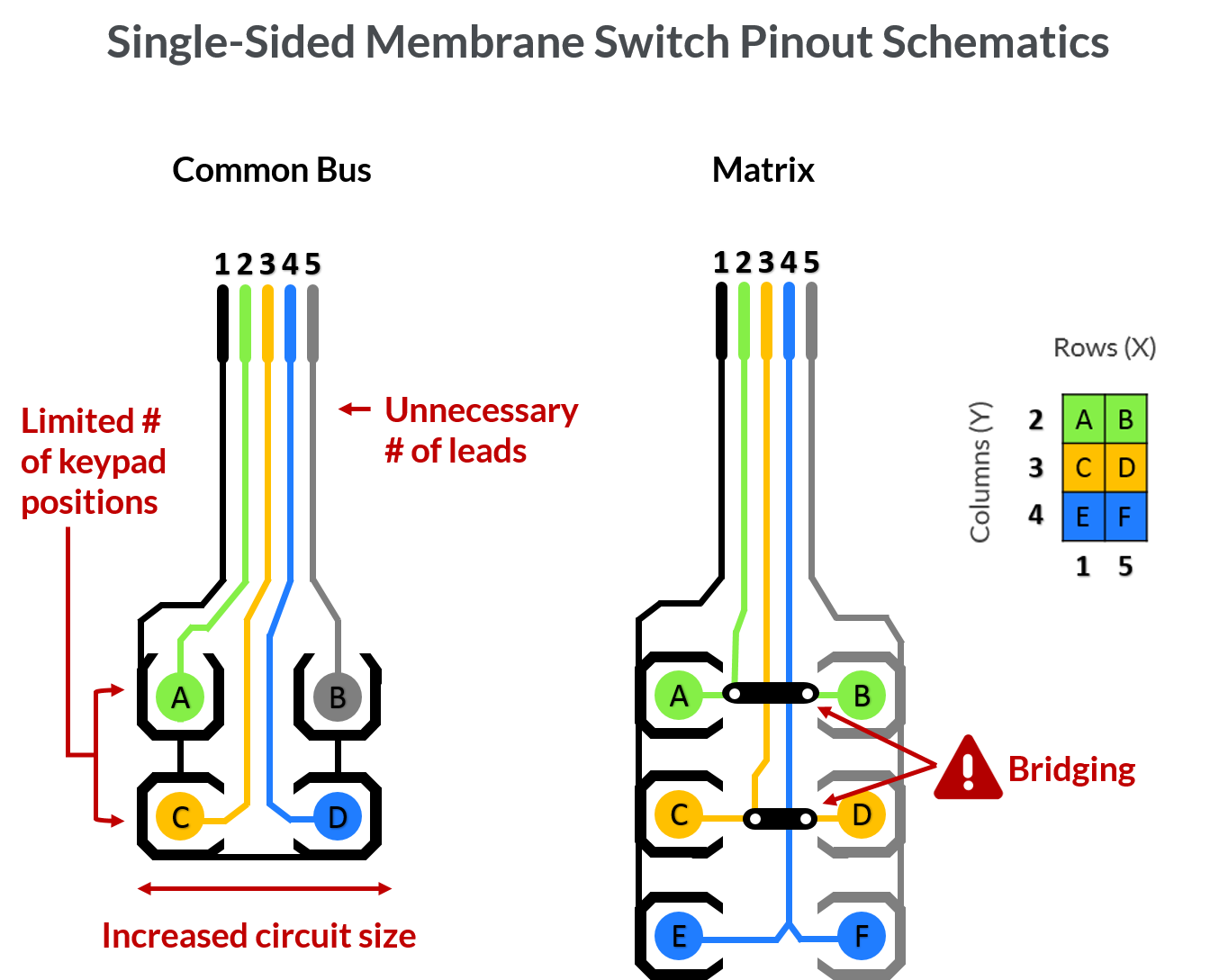

Operating on a simple concept, membrane changes use a split building to register customer input efficiently. Each button is composed of numerous layers, including a printed circuit layer, a spacer layer, and a leading visuals layer, which are created to collaborate perfectly. When a customer presses the leading layer, it presses the spacer layer, bringing the conductive components of the circuit layer right into contact with each various other.

This call produces a shut circuit, signifying the tool to perform a particular feature. The layout permits different configurations, including responsive comments, which can improve the user experience by offering a physical sensation upon activation. The products utilized in membrane buttons commonly consist of versatile substrates, such as polyester or polycarbonate, which ensure resilience and resilience against damage.

Key Advantages of Membrane Layer Switches

Another substantial benefit is their compactness. Membrane layer buttons are thin and light-weight, which allows suppliers to conserve area in their devices without compromising performance. This feature is specifically beneficial in applications where weight and quantity are important factors to consider.

Furthermore, membrane switches are resistant to dirt, moisture, and chemicals, enhancing their toughness. This resilience prolongs their life expectancy and decreases the need for constant replacements, resulting in cost financial savings in time.

Additionally, the tactile comments offered by membrane buttons can be enhanced to improve customer communication. They can consist of features such as elevated switches or distinct clicks, boosting usability and user experience.

Applications Across Industries

Interface gadgets using membrane buttons are common in a large array of industries, showcasing their flexibility and functionality. Membrane Switch. In the clinical industry, membrane switches are important to devices such as analysis equipment and individual tracking systems, where their resilience and ease of cleaning are critical for preserving health standards. In a similar way, in the vehicle market, these switches are utilized in dashboard controls and infomercial systems, offering a sleek and go to my site contemporary interface for users.

Moreover, the customer electronic devices market gain from membrane layer buttons in appliances and portable tools, where portable layout and easy to use user interfaces improve individual experience. Industrial applications additionally take advantage of membrane switches over for control board in machinery and automation systems, emphasizing their effectiveness and resistance to harsh atmospheres.

In the aerospace and protection markets, membrane buttons are utilized in cockpit controls and devices, where reliability and performance under extreme conditions are critical. Additionally, the video gaming sector increasingly incorporates membrane layer switches in controllers and gallery equipments, contributing to an interesting user experience. On the whole, the versatility of membrane layer switches over enables their prevalent usage throughout numerous industries, emphasizing their relevance in modern interface style.

Future Patterns in Membrane Switch Modern Technology

Furthermore, making use of advanced products, such as polycarbonate and polyester films, is anticipated to rise, providing enhanced longevity and resistance to ecological stress factors. These materials add to the total longevity of membrane switches, making them appropriate for harsher commercial applications.

In addition, the incorporation of clever innovation, consisting of IoT connectivity, will allow membrane switches to communicate with other devices and systems, promoting a more interactive customer experience. This trend aligns with the expanding need for smart tools across numerous industries, from healthcare to customer electronics.

Finally, personalization choices are prepared for to broaden, permitting makers to produce bespoke solutions customized to particular customer demands and preferences. These growths will position membrane layer buttons as important elements in the evolution of interface technology.

Verdict

In verdict, membrane changes stand for a critical development in interface modern technology, supplying a trusted and the original source flexible solution for diverse electronic applications. Their layered building and construction helps with portable design, while functions such as tactile responses improve customer communication. The sturdiness versus ecological aspects further strengthens their energy throughout several markets. As innovations in product science and touch noticing modern technologies proceed, the functionality and applicability of membrane layer buttons are anticipated to increase, enhancing their importance in modern-day digital tools.

Report this page